Poorly written work instructions, standard operating procedures, incorrect drawings and blueprints, improperly constructed fixtures, inappropriate production equipment, and poorly designed work station layout are just a few examples which contribute to human error. These poorly written documentations add addition trouble that could've been avoided. It is not unheard of to find components being fabricated according to out of date instructions because the correct information has been delayed in reaching the worker. Poor design and documentation quality is a major cause of product process inefficiencies, leading directly to delays, rework and variations, and contributing to increase project time and cost, for both the client and your company. But, proper documentation is not just restricted to engineering paperwork, no, it involves every person working in that company. Lets see how poor documentation can delay even the best companies.

Manufacturing is extremely competitive and becoming more intense as customers demand more services. It is important to manage not only control over its overhead, but also understand how improving material handling can reduce direct cost. This article will go over the hiding cost associated with material waste and the byproducts of it.

How to Increase the Speed of Innovation with Better Engineering Design

Posted by Lucas Leão Apr 30, 2015

A financial crisis that brings down the economy can be devastating especially for businesses.It may have direct and indirect effect on the growth and development of your business. Companies can struggle during financial crisis and can take a toll on the interest and investments of many. An economic crisis can have detrimental effects on both small and larger companies. Since, it can take a good amount of time for an economy crisis to recover, businesses who are affected at the start of the falling economy will most likely endure the negative effects of it for a longer period of time.

Also available in: Português / Spanish

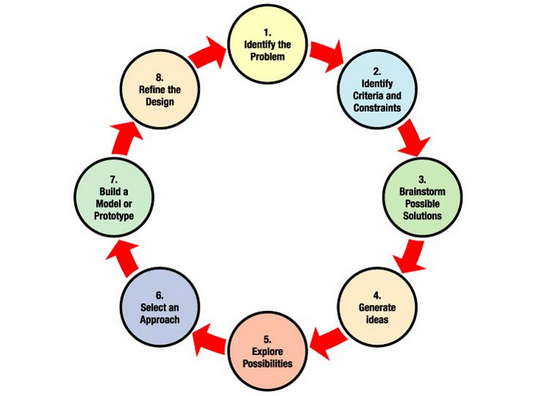

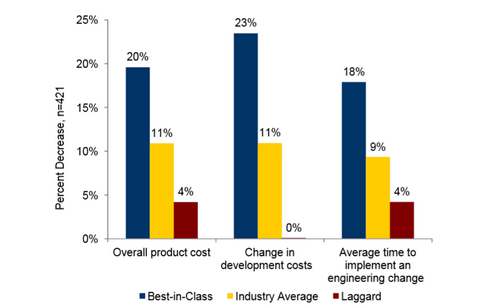

The need to get products to market more quickly is prompting companies to take a closer look at how work is done in CAD. Advanced capabilities within CAD tools can allow companies to remove tedious activities and improve design productivity. This article takes a look into the capabilities of CAD software and how it can be used to improve the engineering design process.CAD A.K.A Computer Aided Design is a highly sophisticated software for modeling engineering designs. CAD software offers many tools and features for modeling that weren’t available to our engineering predecessors. Even with the advancements in CAD, currently software developers are creating newer platforms that focus on user interface and performance.

Inefficiencies in CAD software still exist and can create a burden for engineers. Looking at what CAD software issues exist greatly increase your chances of recognizing and preparing designers in how to avoid them. This article will go into a few of the most common inefficiencies that exist in today’s CAD softwares and what you can do about them.