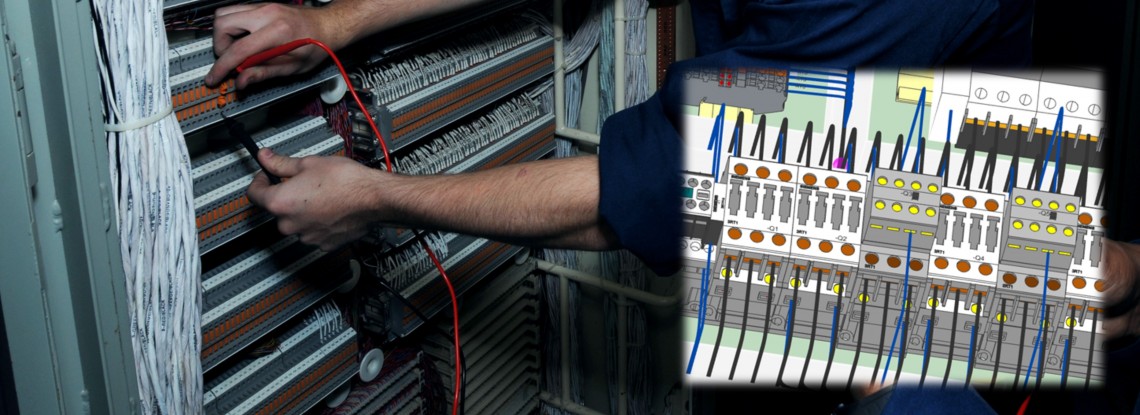

Power distribution systems need detailed care and consideration when planning and designing. The power system is crucial to keep day to day operations functioning properly. Let us look at some of the important aspects distribution system planning and design.

Programmable logic controllers, or more commonly PLCs, are digital computers used for automating specific tasks or processes for a variety of applications. They can control machinery on assembly lines, roller coasters at amusement parks, or light fixtures. Nowadays, industrial automation is growing in demand for manufacturing facilities globally. Automation is becoming a central aspect in manufacturing as facilities are facing thin profit margins, and still working within just-in-time manufacturing methods. Companies are understanding that in order to deliver for these processes they must meet customer demand while operating at lower costs, mass production, customizable, and flexibility. The main objective of this article is to help facilities understand the benefit of switching from rough manual production lines to automating specific tasks with PLCs.

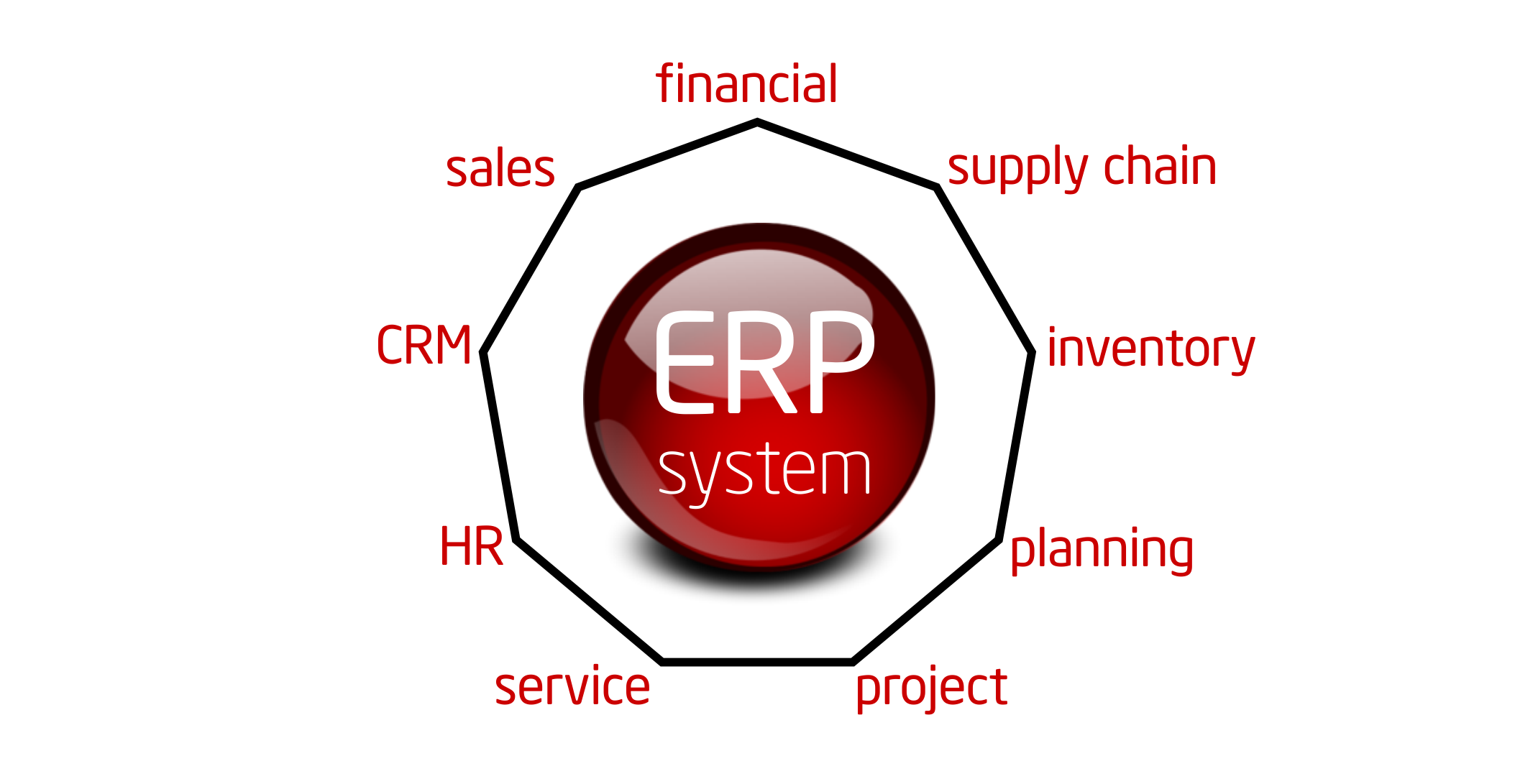

Advantages of Integrating your Electrical Design Process with your ERP System

Posted by Lucas Leão Dec 16, 2015

Having effective and efficient design process is essential in today’s world for competing with the top tier companies. A well structured system needs to be embedded in all independent stations throughout the company to set up an information network where information flows freely from one person to the next.

Work stations that work independently, lack of inventory accountability, misallocated resources, and poor documentation can inhibit even the mightiest of giants. Have a system installed that can communicate to everyone in the company and provide necessary information for product development, management, and manufacturing can speed up progress and efficiency.

This article takes a look at what the advantages are of ERP software and how it can benefit your company in all forms of design and manufacturing.

ERP systems have been around for a long time, and most are quite familiar about what benefits it can bring to a company. There are several case studies about how installation of an ERP system has made many corporate operations more streamlined, efficient, and agile. The situation is even better due to a large number of solutions that are available to cater the different companies in terms of size and business verticals.

Due to the numerous types of designs and implementation processes, there are a variety of prototype methods available to physically, or virtually, represent an idea. Mechanical and electrical engineering, electronics, computer programming, software, and computer engineering are just a few of the fields that are known for prototyping.